C70600 Copper Nickel 90/10

C70600 Copper Nickel 90/10, also known as Cupronickel 90/10, is a copper alloy with a composition of approximately 90% copper and 10% nickel, along with trace amounts of other elements. Here is a technical description of C70600 Copper Nickel 90/10 and its common uses:

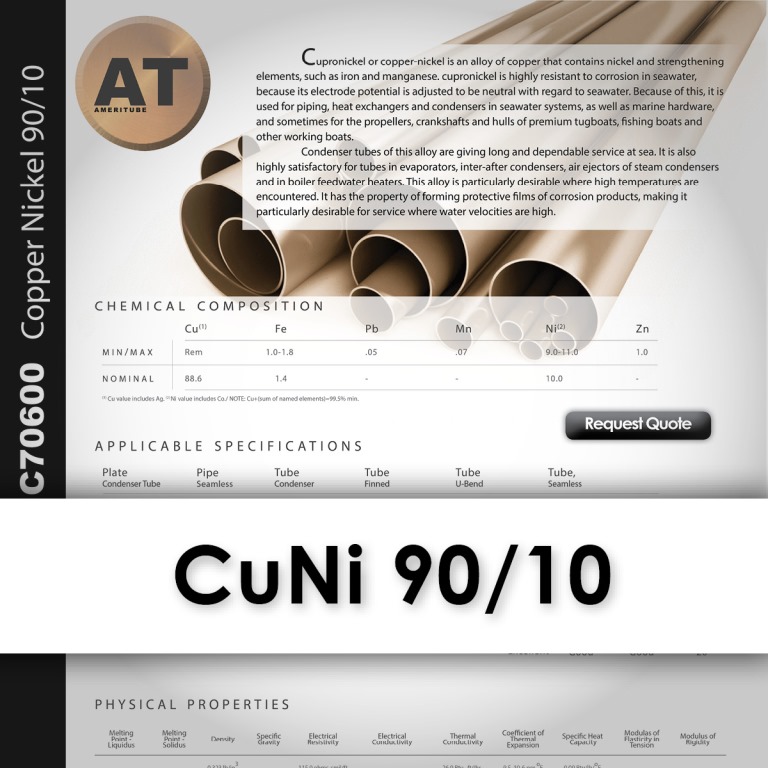

Composition:

- Copper (Cu): Approximately 88.6-90.4%

- Nickel (Ni): Approximately 9-11%

- Iron (Fe): Maximum 1.8%

- Manganese (Mn): Maximum 1%

Mechanical Properties:

- Tensile Strength: Typically ranges from 310 MPa (45,000 psi) to 480 MPa (70,000 psi)

- Yield Strength: Generally around 105-240 MPa (15,000-35,000 psi)

- Elongation: Typically 25-35%

Physical Properties:

- Density: Approximately 8.94 g/cm³ (0.323 lb/in³)

- Melting Point: Approximately 1170-1240°C (2140-2260°F)

Corrosion Resistance: C70600 Copper Nickel 90/10 exhibits excellent resistance to corrosion in various environments, especially seawater and brackish water. It is highly resistant to biofouling, erosion, and stress corrosion cracking, making it suitable for marine and offshore applications.

Machinability: Copper Nickel 90/10 is known for its good machinability, allowing for ease of fabrication and machining processes. However, its high strength and work hardening characteristics may require appropriate machining techniques and tools.

C70600 Copper Nickel 90/10 is an alloy in the copper nickel family of alloys. The alloy is extremely versatile known for its high heat transfer, ductility, and corrosion resistance. Copper-nickel (also known as cupronickel) alloys are widely used for marine applications due to their excellent resistance to seawater corrosion, low macrofouling rates, and good fabricability. They have provided reliable service for decades while offering effective solutions to today’s technological challenges. (copper.org)

Cupronickel or copper-nickel is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. cupronickel is highly resistant to corrosion in seawater, because its electrode potential is adjusted to be neutral with regard to seawater. Because of this, it is used for piping, heat exchangers and condensers in seawater systems, as well as marine hardware, and sometimes for the propellers, crankshafts and hulls of premium tugboats, fishing boats and other working boats.

Condenser tubes of this alloy are giving long and dependable service at sea. It is also highly satisfactory for tubes in evaporators, inter-after condensers, air ejectors of steam condensers and in boiler feedwater heaters. This alloy is particularly desirable where high temperatures are encountered. It has the property of forming protective films of corrosion products, making it particularly desirable for service where water velocities are high.

Request a Quote

.Ameritube has been involved in the manufacturing, distribution, use, and development of new technologies in Copper Nickel for the last 20 years. C70600 Copper Nickel 90/10 has seen technological improvements, process and melt developments and testing requirements that Ameritube and its personnel have deep expertise in. From casting the alloy, developing the production processes, pilgering, drawing, annealing and finishing, Ameritube is a recognized industry expert in the manufacturing of quality C70600 Copper Nickel tube and pipe.

Ameritube has been providing C70600 Copper Nickel 90/10 according to the following standards:

- ASME SB-111

- ASME SB-466

- ASTM B-111

- ASTM B-466

- MIL-T-15005f

- MIL-T-16420k Class 200, 700, 1650, 3300, and 6000

Data Sheet on Copper Nickel 90/10 can be found here.

Uses and Applications:

-

Marine and Offshore Applications: C70600 Copper Nickel 90/10 is extensively used in marine environments due to its exceptional resistance to seawater corrosion. It is utilized in seawater cooling systems, heat exchangers, condensers, piping, fittings, and shipbuilding components.

-

Heat Exchangers and Condensers: The excellent thermal conductivity and corrosion resistance of Copper Nickel 90/10 make it suitable for heat exchangers, condensers, and similar applications in various industries, including power generation, chemical processing, and HVAC systems.

-

Desalination Plants: C70600 Copper Nickel 90/10 is employed in desalination plants for its resistance to both seawater corrosion and biofouling. It is used in heat exchangers, tubing, and piping systems for efficient and reliable operation.

-

Offshore Oil and Gas Industry: The corrosion resistance and mechanical strength of Copper Nickel 90/10 make it suitable for offshore oil and gas applications, including piping, tubing, and components in subsea systems, platforms, and pipelines.

-

Automotive Industry: Copper Nickel 90/10 finds application in automotive cooling systems, specifically in radiators, heater cores, and oil coolers, due to its corrosion resistance and thermal conductivity.

-

Coinage: Copper Nickel 90/10 is used in the manufacturing of coins and coinage due to its durability, resistance to wear, and attractive appearance.

-

Industrial Applications: It is also utilized in various industrial applications such as condenser plates, power plant water boxes, and chemical process equipment where corrosion resistance and thermal conductivity are essential.

These are some of the most common uses of C70600 Copper Nickel 90/10. Its excellent corrosion resistance, mechanical properties, and thermal conductivity make it a reliable choice in demanding environments and applications where resistance to seawater, corrosion, and biofouling is required.