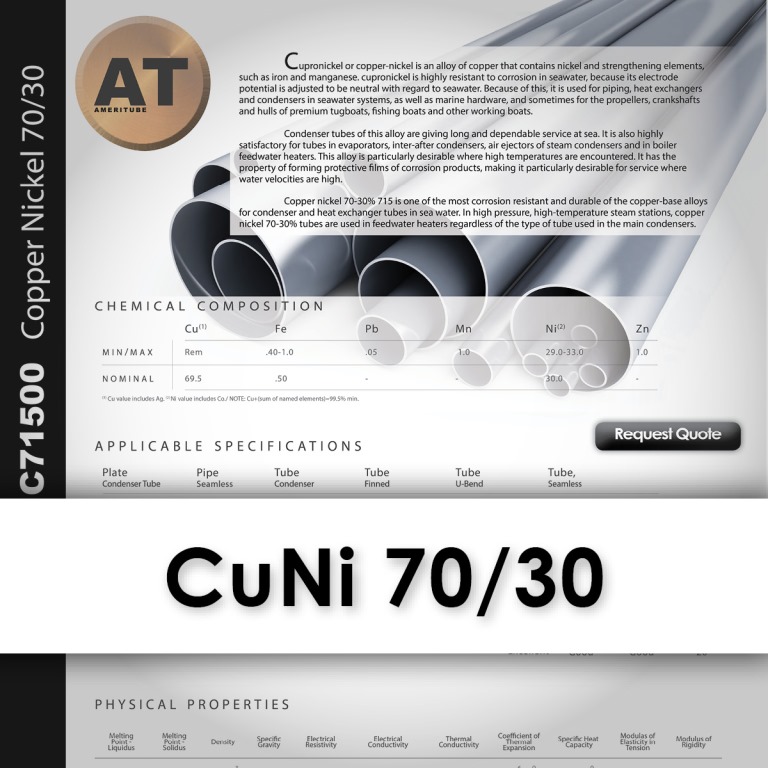

C71500 Copper Nickel 70/30

Cupronickel or copper-nickel is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. cupronickel is highly resistant to corrosion in seawater because its electrode potential is adjusted to be neutral with regard to seawater. Because of this, it is used for piping, heat exchangers, and condensers in seawater systems, as well as marine hardware, and sometimes for the propellers, crankshafts, and hulls of premium tugboats, fishing boats, and other working boats.

Copper nickel 70-30% 715 is one of the most corrosion-resistant and durable copper-base alloys for condenser and heat exchanger tubes in seawater. In high-pressure, high-temperature steam stations, copper-nickel 70-30% tubes are used in feedwater heaters regardless of the type of tube used in the main condensers.

Ameritube has been providing C71500 Copper Nickel 70/30 according to the following standards:

- ASME SB-111

- ASME SB-466

- ASTM B-111

- ASTM B-466

- MIL-T-15005f

- MIL-T-16420k Class 200, 700, 1650, 3300, and 6000

C71500 Copper Nickel 70/30, also known as Cupronickel 70/30, is a copper alloy with a composition of approximately 70% copper and 30% nickel, along with trace amounts of other elements. Here is a technical description of C71500 Copper Nickel 70/30:

Composition:

- Copper (Cu): Approximately 65.0-71.5%

- Nickel (Ni): Approximately 29.0-33.0%

- Iron (Fe): Maximum 0.4%

- Manganese (Mn): Maximum 1.0%

- Zinc (Zn): Maximum 1.0%

Mechanical Properties:

- Tensile Strength: Typically ranges from 372 MPa (54,000 psi) to 552 MPa (80,000 psi)

- Yield Strength: Generally around 138-483 MPa (20,000-70,000 psi)

- Elongation: Typically 30-45%

Physical Properties:

- Density: Approximately 8.94 g/cm³ (0.323 lb/in³)

- Melting Point: Approximately 1170-1240°C (2140-2260°F)

Corrosion Resistance: C71500 Copper Nickel 70/30 exhibits excellent resistance to corrosion in various environments, especially in seawater and brackish water. It provides high resistance to stress corrosion cracking and biofouling, making it suitable for marine and offshore applications.

Machinability: Copper Nickel 70/30 has good machinability, allowing for ease of fabrication and machining processes. However, its high strength and work hardening characteristics may require appropriate machining techniques and tools.

Request a Quote

C71500 Copper Nickel 70/30 tube and pipe are highly versatile and widely used in various industries due to their excellent corrosion resistance, high strength, and superior thermal conductivity. Here are some common applications and uses of C71500 Copper Nickel 70/30 tube and pipe:

- Marine and Offshore Applications: C71500 Copper Nickel 70/30 tube and pipe are extensively used in marine environments for applications such as seawater cooling systems, heat exchangers, condensers, and shipbuilding components. Their exceptional resistance to seawater corrosion and biofouling make them an ideal choice for these demanding applications.

- Oil and Gas Industry: Copper Nickel 70/30 tube and pipe are utilized in the oil and gas industry for various applications, including offshore platforms, subsea pipelines, and oil refineries. Their corrosion resistance and high mechanical strength make them suitable for handling corrosive fluids and withstanding high-pressure environments.

- Power Generation: C71500 Copper Nickel 70/30 tube and pipe find application in power plants for heat exchangers, condensers, and steam generation systems. Their excellent thermal conductivity ensures efficient heat transfer, while their corrosion resistance makes them suitable for handling various cooling and heating fluids.

- Desalination Plants: Copper Nickel 70/30 tube and pipe are used in desalination plants for seawater intake and brine discharge systems. Their resistance to corrosion and fouling by salts and marine organisms makes them ideal for these harsh environments.

- Chemical Processing: Due to their excellent resistance to corrosive chemicals, C71500 Copper Nickel 70/30 tube and pipe are utilized in chemical processing plants for conveying and handling corrosive fluids, including acids, alkalis, and salt solutions.

- HVAC and Refrigeration: These copper nickel tubes and pipes are employed in HVAC (heating, ventilation, and air conditioning) and refrigeration systems for their superior thermal conductivity and resistance to corrosion. They ensure efficient heat transfer and reliability in these applications.

- Automotive and Transportation: Copper Nickel 70/30 tube and pipe find use in automotive and transportation industries for applications such as brake lines, fuel lines, and hydraulic systems due to their corrosion resistance and mechanical strength.

These are just a few examples of the many applications where C71500 Copper Nickel 70/30 tube and pipe are utilized. Their unique combination of properties makes them suitable for a wide range of demanding industries and environments, where durability and resistance to corrosion are paramount.