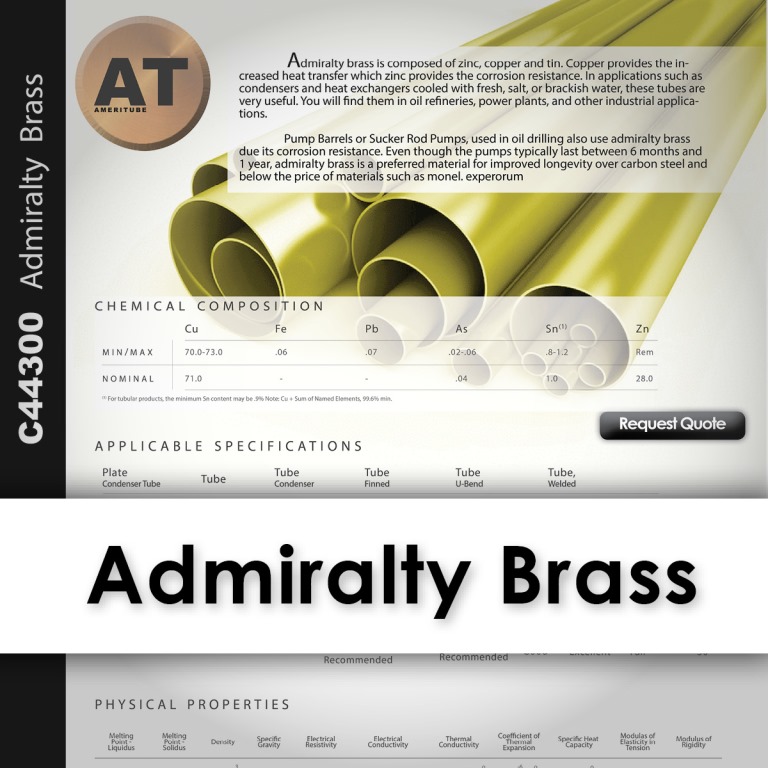

C44300 Admiralty Brass

Admiralty brass is composed of zinc, copper and tin. Copper provides the increased heat transfer which zinc provides the corrosion resistance. In applications such as condensers and heat exchangers cooled with fresh, salt, or brackish water, these tubes are very useful. You will find them in oil refineries, power plants, and other industrial applications.

Pump Barrels or Sucker Rod Pumps, used in oil drilling also use admiralty brass due to its corrosion resistance. Even though the pumps typically last between 6 months and 1 year, admiralty brass is a preferred material for improved longevity over carbon steel and below the price of materials such as monel 400.

One of the most commonly used heat exchange alloys, its usage goes back for over 70 years. Successfully built and maintained C44300 admiralty brass heat exchangers and power plant condensers have been in service for over fifty years. Ameritube has been manufacturing, distributing, testing, and supplying this alloy for over 12 years.

Combining copper, zinc and tin, C44300 admiralty brass is a low-cost alloy with good heat transfer and high corrosion resistance. Ameritube has to be your choice in admiralty brass both for heat transfer and pump barrel applications. Let us put our deep experience in manufacturing this alloy into your next application.

Ameritube has been providing C44300 Admiralty Brass according to the following standards:

- ASME SB-111

- ASTM B-111

- ASTM B135

- API 11AX

To learn more about this alloy, click here.

Our C44300 tubing is a high-quality product that offers exceptional corrosion resistance, excellent thermal conductivity, and superior formability, making it an ideal choice for various industries and applications.

C44300 tubing is widely used in heat exchanger systems, including HVAC, refrigeration, power plants, and industrial process cooling. With its impressive thermal conductivity, it ensures efficient heat transfer, enhancing the performance and energy efficiency of these systems.

In plumbing and water systems, our C44300 tubing is highly reliable. Its corrosion resistance and antimicrobial properties make it suitable for carrying potable water, hot water, and chilled water. Whether for residential or commercial applications, our C44300 tubing provides durable and safe water distribution.

For condenser applications, our C44300 tubing excels in facilitating the efficient transfer of heat from vapor to liquid. It is widely utilized in air conditioning units, refrigeration systems, and power generation plants, delivering reliable performance and contributing to optimal system functionality.

The oil and gas industry also benefits from our C44300 tubing, which is utilized in oil coolers, gas pipelines, and offshore platforms. Its corrosion resistance and thermal conductivity make it suitable for handling various fluids and contributing to the reliable operation of oil and gas systems.

Automotive and transportation industries rely on our C44300 tubing for applications such as fuel lines, hydraulic systems, and radiators. Its corrosion resistance, formability, and durability make it an excellent choice in these demanding environments.